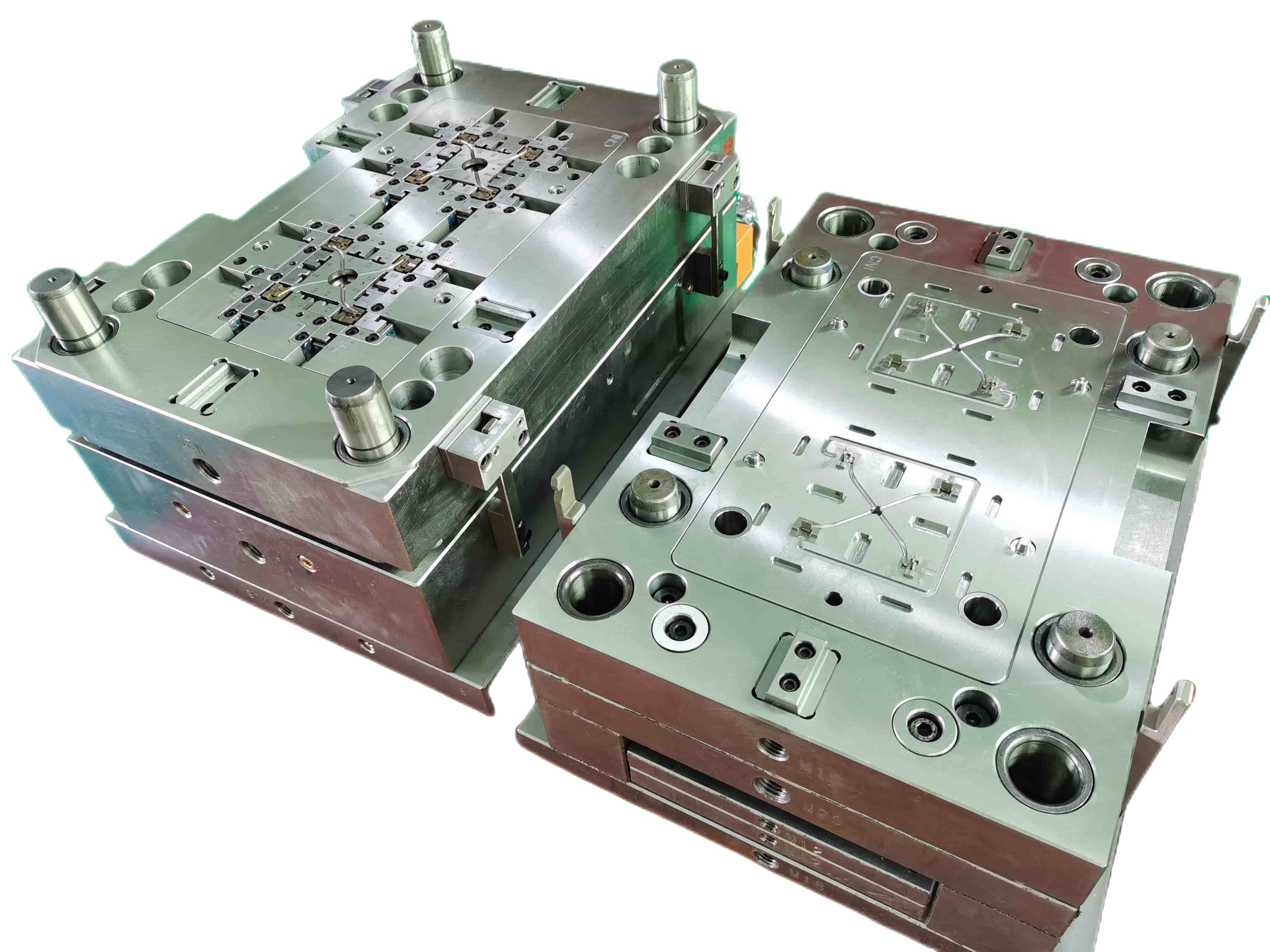

| Mea Hana a me ke ʻano | ʻO nā ʻāpana kikoʻī uila i hana ʻia e ka multicavity plastic injection mold, | |||||

| inoa hapa | Mea hoʻohui kelepona | |||||

| Resin | ʻO nā mea hao pauka | |||||

| No. o ka lua | 1*8 | |||||

| Kumu Mold | S50C | |||||

| Steel of cavity&Core | S136 HRC 52-54 | |||||

| Kaumaha mea hana | 450KG | |||||

| Ka nui o ka mea hana | 450X350X370mm | |||||

| E kaomi iā Ton | 90T | |||||

| Ola mold | 1000000 pana | |||||

| Pūnaehana hoʻopio | Kukini wela, 2pcs Mold-master hot tips | |||||

| Pūnaehana hoʻoluʻu | ʻO ka hoʻoluʻu ʻana i ka ʻaila, ka mahana o ka mold 120 degere | |||||

| Pūnaehana Ejection | ʻElua ʻanuʻu ejection | |||||

| Nā kiko kūikawā | ʻO nā mea hoʻoheheʻe ʻia ka pauka, ka hoʻoheheʻe pololei ʻana, ka mea holo wela, ka 8 cavity mold, ka manawa pōkole pōkole | |||||

| Nā pilikia | ʻO ka hoʻomanawanui pololei kiʻekiʻe, ʻo ka ʻeleʻele wela kiʻekiʻe, ka manawa pōkole e hana ana i ka manawa alakaʻi a me ka manawa pōkole.ʻO ka mea ʻo Powder metallurgy material me ka manawa pōkole a me ke koi kiʻekiʻe o nā mīkini injection. | |||||

| Ka manawa o waena o ka hoʻomaka a i ka wā pau | 4 pule | |||||

| Pūʻolo | Noho ʻo Mold ma Kina no ka hana ʻana i ka palaka | |||||

| Hoʻopili i nā mea | ʻO ka hōʻoia ʻana o ke kila, ka hoʻolālā mea hana 2D & 3D hope loa, ka palapala holo wikiwiki, nā ʻāpana ʻokoʻa a me nā electrodes… | |||||

| Hoʻoemi | 1.005 | |||||

| Hoʻopau ʻili | SPI B-1 | |||||

| Ka manawa pōʻaiapili hoʻoheheʻe ʻia | 9 kekona | |||||

| ʻO ka lua o ka mālama ʻana i nā huahana ma hope o ka hana ʻana | Hana wela no nā huahana i hoʻoheheʻe ʻia | |||||

| Hoʻokuʻu aku i | Noho ʻo Mold ma Kina no ka hana ʻana i ka palaka | |||||

ʻO nā pilikia

ʻO ka hoʻomanawanui pololei kiʻekiʻe, ʻo ka ʻeleʻele wela kiʻekiʻe, ka manawa pōkole e hana ana i ka manawa alakaʻi a me ka manawa pōkole.

ʻO ka mea ʻo Powder metallurgy material me ka manawa pōkole a me ke koi kiʻekiʻe o nā mīkini injection.

He aha ka pauda metallurgy?

ʻO ka pauka metallurgy kahi kaʻina hana e hoʻohana ana i ka hoʻopili kaomi ʻana a me ka sintering o nā ʻāpana metala e hana i nā ʻāpana like ʻole a me nā ʻāpana.ʻO ke kaʻina hana ka hui pū ʻana i nā metala pauka e like me ka hao, ka aluminika, ke keleawe, ke kila kila a me ka cobalt me nā lubricants a me nā mea hoʻopaʻa paʻa ma mua o ke kau ʻana iā lākou i nā pae kiʻekiʻe o ke kaomi.A laila hoʻomehana ʻia ka hui ʻana a hiki i ka hui ʻana o nā mea kemika, e hana ana i nā ʻāpana i ʻoi aku ka ikaika ma mua o nā mea i hoʻolei ʻia a i ʻole nā mīkini.

Ma muli o kāna versatility, ua lilo ka pauka metallurgy i mea kaulana no ka hana ʻana i nā ʻāpana paʻakikī i hoʻohana ʻia i ka automotive, aerospace a me nā noi uila mea kūʻai aku.

He aha ka mold wela kiʻekiʻe?

ʻO ka hoʻoheheʻe wela kiʻekiʻe kahi ʻano o ka hana hoʻoheheʻe ʻia e hoʻohana ai i nā mahana kiʻekiʻe a me nā kaomi e hana i nā ʻāpana me ka ikaika kiʻekiʻe a me ka lōʻihi.Hoʻohana ʻia ke kaʻina hana ma ka hoʻomehana ʻana i nā mea thermoplastic maka a hiki i ka hoʻoheheʻe ʻia ʻana a laila hoʻokomo ʻia i loko o kahi poʻi paʻa kahi i paʻa ai ma lalo o ke kaomi.ʻO ka wela mai ka resin hoʻoheheʻe ʻia i hui pū ʻia me ke kaomi e hana ai ka mea i ke ʻano i makemake ʻia ma mua o ka hoʻoluʻu ʻana.Hāʻawi kēia kaʻina hana i ka hana ʻana i nā ʻāpana paʻakikī i kū i ka wela wela a me nā kemika corrosive, e hana maikaʻi iā lākou no ka hoʻohana ʻana i nā ʻoihana e like me ka automotive, aerospace, nā mea lapaʻau a me nā uila.

Loaʻa i nā mea Plastic maʻamau: PEEK, PPSU, ULTEM® (Polyetherimide, PEI), Celazole®, Vespel®, Torlon® (Polyamide-imide) a pēlā aku.

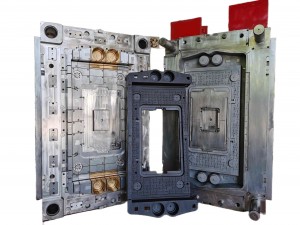

Hoʻolālā mold no ka poʻi wela kiʻekiʻe

I ka hoʻolālā ʻana i nā mole no nā plastik wela kiʻekiʻe he mea nui e hoʻokomo i nā ala hoʻololi wela a me ka hoʻohana ʻana i nā pine wela e hōʻoia i ka maʻalili like ʻana o ka plastic i ka wā o ke kaʻina hana hoʻoheheʻe.

Eia hou, he mea nui ke koho ʻana i ka mea poni kūpono no ka hana ʻana i nā ʻāpana hiki ke kū i nā wela wela me ka ʻole o ka warping a i ʻole ka pohā.

Ma kēia papahana, hoʻohana mākou i ke kila o S136 me HRC 52 ~ 54, kiʻekiʻe loa ka nui o ka hana, pono nā ʻāpana 100000pcs i kēlā me kēia lā, no laila ua hoʻohana mākou i ka 8 cavity mold a hana i nā kope he nui e hālāwai me ka noi nui.No ka hoʻoluʻu ʻana, hoʻoluʻu ʻia e ka ʻaila a hiki i ka mahana o ka mold i 120 degere.ʻO ka manawa pōʻai he 9 kekona a ua hoʻohana mākou i 2 mau ʻanuʻu ejection no ka hoʻokuʻu ʻana i nā ʻāpana.E mālama ʻia kēia ʻāpana ma hope o ka hoʻoheheʻe ʻana.

ʻO ka mea hana hoʻoheheʻe ʻia ʻo 8 cavity kiʻekiʻe wela hoʻoheheʻe ʻia.

ʻO ka plastik nā mea hoʻoheheʻe metala a ʻo nā ʻāpana i hoʻoheheʻe ʻia e pono ai ka mālama wela no ka mea ʻo ia ka mea hoʻohui kelepona.

He pōkole loa ka manawa pōʻaiapili hoʻoheheʻe ʻia, 9 kekona no hoʻokahi pana.

Ua hana mākou i nā mea hana kope he nui no kēia mea kūʻai.Hana maikaʻi loa kā mākou mea hoʻolālā, no ka DFM, ua hoʻopau ʻia i loko o 1 lā, 2D hoʻolālā i loko o 2 mau lā, a me 3D i loko o 3 mau lā.

ʻO ka manawa alakaʻi hana mold he 4 wiki.

No ka hoʻolālā mold, i ka wā e koʻikoʻi loa ka manawa, hana maʻamau mākou i ke kaha kiʻi 3D ma hope o DFM, akā ʻoiaʻiʻo, pono e kau ʻia ma ka ʻae ʻana o nā mea kūʻai aku.

2D hoʻolālā

3D mold design

3D mold design

FAQ

ʻO kā mākou ʻoihana koʻikoʻi no ka hana ʻana i ka mold injection plastic, die cast mold making, plastic injection molding, die casting (Aluminum), precision machining a me ka prototyping wikiwiki.Hāʻawi pū mākou i nā huahana i hoʻohui ʻia me nā ʻāpana silika, nā ʻāpana stamping metala, nā ʻāpana extrusion a me nā stainle

ʻAʻole, ʻo mākou ka mea hana mold maoli a me ka hale hana hoʻoheheʻe plastic injection.Hiki iā mākou ke hāʻawi i ke kiʻi hoʻopaʻa inoa no ka kuhikuhi a me nā ʻike ʻē aʻe āu e makemake ai inā pono.I kēia manawa, hiki iā ʻoe ke kipa mai iā mākou i kēlā me kēia manawa, ʻaʻohe koho.

Hāʻawi ka hui Suntime i ke ʻano hana lawelawe 24/7.No nā lā hoʻomaha lehulehu o Kina, hiki i kā mākou mea kūʻai aku a me nā ʻenekinia ke lawe i nā hana keu no kekahi o kāu pilikia.A i ka wā e pono ai, e hana mākou i ka mea maikaʻi loa e noi i nā limahana e lawe i nā hana keu i ka wā hoʻomaha ma ka hoʻololi ʻana i ke ao a me nā hoʻololi pō e hoʻokō i kāu mau koi wikiwiki.

Ua loaʻa iā mākou ma mua o ʻumi mau makahiki i ka hoʻolaha ʻana i ka ʻike i ka mākeke honua, lawe ʻia i ka ʻili i hoʻoheheʻe ʻia i waho, ka ʻōpala hoʻoheheʻe make, nā ʻāpana hoʻoheheʻe make, nā huahana i hoʻoheheʻe ʻia a me nā ʻāpana mīkini CNC etc.

No ka hana ʻana i ka mold, loaʻa iā mākou ka CNC, EDM, Grinding machines, milling machines, drilling machines, etc.No ka hoʻoheheʻe ʻana i ka plastik maʻamau, loaʻa iā mākou nā mīkini injection 4 mai 90 ton a i 400 ton.No ka nānā ʻana i ka maikaʻi, loaʻa iā mākou hexagon CMM, Projector, mea hōʻike paʻakikī, ana kiʻekiʻe, vernier caliper a pēlā aku.

E loaʻa i kahi DFM manuahi i kēia lā!

-

Plastic injection molding project mai Rapid p...

-

ʻO ka nui ka nui o ka ʻilika injection mold no ka automotive...

-

Plastic tooling ʻohana mold automotive huelo lig...

-

Injection multi cavity mold no nā pāpale o packa...

-

Plastic injection mold hookomo mold no Automo...

-

Kiʻekiʻe aniani fiber Nylon mea mold mea paahana no...