5 ʻAno hoʻoheheʻe ʻia e pili ana i ka maʻamau US SP1-SPE

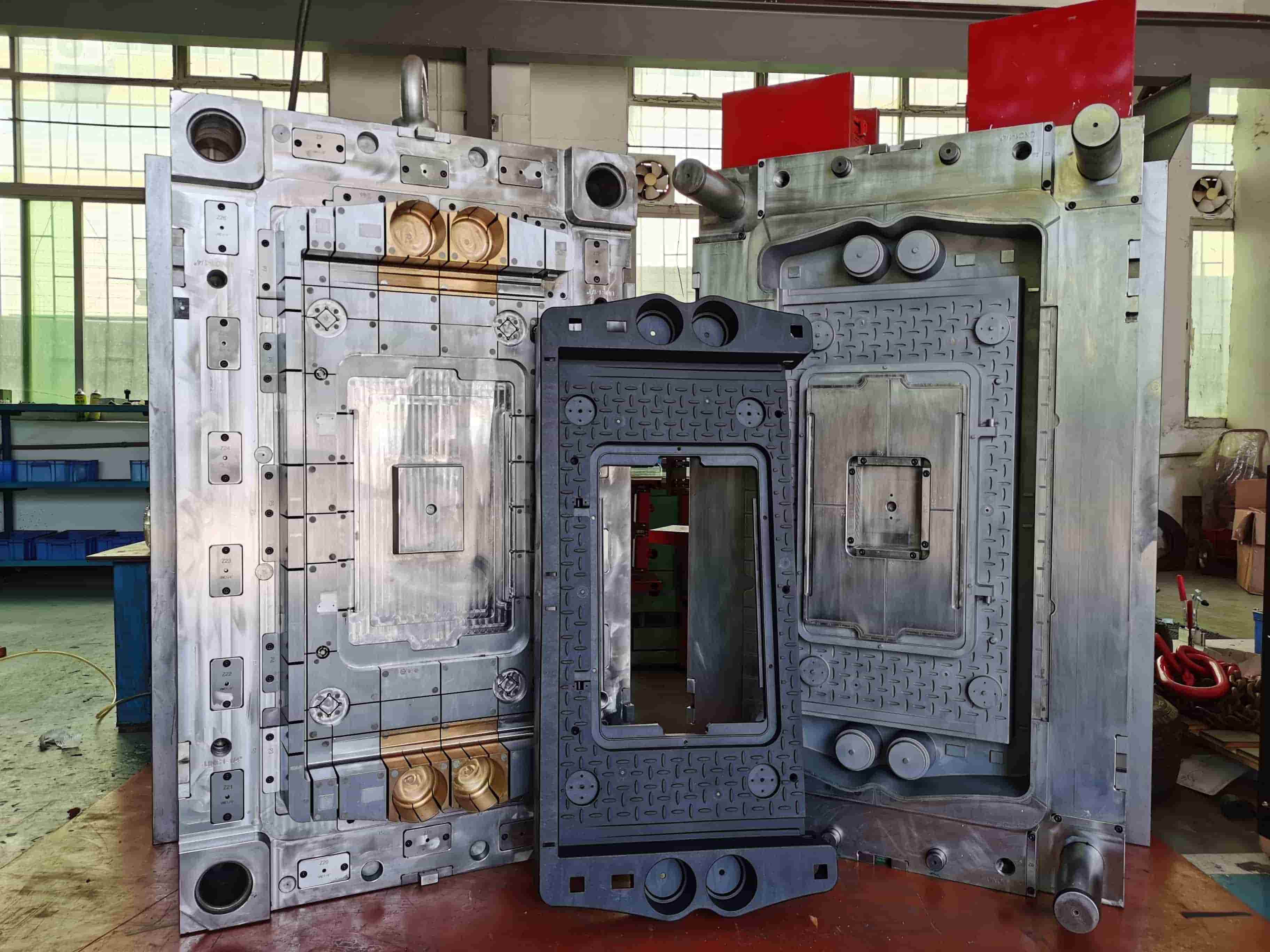

Inā pono ʻoe e hoʻomohala i kahi huahana a i ʻole papahana, ʻo nā lako lako mea he mea hiki ʻole ke ʻae ʻia, a kaulana loa nā pahu plastik i kēia manawa.Pono e hoʻokaʻawale ʻia ka hana ʻana o nā pūpū plastik mai nā mold injection.Ma keʻano he mea hana a me ka mea kūʻai aku i ka Chinese injection mold, loaʻa iā mākou ma mua o 10 mau makahiki o kaʻikeʻana i waho a uaʻike mākou i nā koi o nā mea kūʻai ma nā'āina likeʻole.I kēia lā e kamaʻilio mākou e pili ana i ke ʻano o nā ʻāpana mold o ka maʻamau US SP1-SPE, a ke manaʻo nei au e pono ia iā ʻoe.

1. Papa 101 molds (SP1-SPE maʻamau 1,000,000 pia a oi aku paha, lōʻihi lōʻihi precision hana poni)

1).Pono nā kaha kiʻi kikoʻī o ka mold structure;

2).ʻO ka paʻakikī liʻiliʻi o ka mea paʻa ʻole ʻo 28HB (DME #2 kila / aliʻi mea electroplating nickel / P20 electroplating Nickel);

3).Pono e hoʻopaʻakikī ʻia ke kila o ka module i loko me ka glue i 48 ~ 52HRC, a ʻo nā ʻāpana ʻē aʻe e like me nā kūlana lālani, paʻi paʻa, beading, etc.

4).Pono nā pou alakaʻi i ka pā ejector;

5).Nā lālani

6).Inā pono, pono e loa'a ka mana wela i ka po'i luna, lalo a me ke kūlana lālani;

7).No nā kahawai wai a pau, ʻōlelo ʻia e hoʻohana i ka nickel electroless dipping a i ʻole 420 stainless steel ma ke ʻano he template, hiki ke pale i ka ʻōpala a hoʻomaʻemaʻe i ka ʻōpala;

8).Pono ka laka pololei a i ʻole ka laka oblique.

2. Type 102 molds (ʻaʻole iʻoi aku ma mua o 1,000,000 beer, hana nui o nā molds)

1).Pono ʻia ke kiʻikuhi kikoʻī o ka mold structure;

2).ʻO ka liʻiliʻi o ka paʻakikī o ka mold base material he 165BHN (DME #2 steel / AISI1050);

3).ʻO nā modula kūloko me nā kūlana glue Pono e hoʻopaʻapaʻa ʻia ke kila i ka liʻiliʻi o 48 ~ 52HRC, a pono e mālama ʻia nā ʻāpana pono ʻē aʻe ma ke ʻano like;

4).Paipai ʻia e hoʻohana i nā laka pololei a i ʻole nā laka oblique;

5).Pono paha kēia mau mea a ʻaʻole paha, ma muli o ka nui o ka hana hope.Manaʻo ʻia e haʻi i ka wā e hoʻohana ai i kēia mau mea, e nānā inā pono: A. Ejector plate guide post, B. Raw position hard sheet, C. Electroplating water delivery hole, D. Electroplating mold cavity.

3. ʻAno 103 molds (emi iho ma mua o 500,000 beers, medium-volume production molds)

1).Pono ke kiʻikuhi kikoʻī o ka mold structure;

2).ʻO ka liʻiliʻi o ka paʻakikī o ka mold base material he 165BHN (DME #1 kila / 1040 kila / S50C);

3).ʻO ka mea kila o ka'ōpala i loko he P20 (28 ~ 32HRC) aiʻole ka paʻakikī kiʻekiʻe (36 ~ 38HRC);

4).ʻO ke koena o nā koi e pili ana i nā pono.

4. ʻAno 104 molds (emi iho ma mua o 100,000 beer, liʻiliʻi hoʻoheheʻe ʻia)

1).Pono ʻia ke kiʻikuhi kikoʻī o ka mold structure;

2).Hiki ke hoʻohana ʻia ke kila māmā a i ʻole alumini (1040 kila) no ka mold base material P20 (28~32HRC);

3).Hiki ke hoʻohana ʻia nā ʻeleʻele kūloko i ka Aluminum, ke kila māmā a i ʻole nā mea metala ʻē aʻe i ʻae ʻia;

4).ʻO nā koi ʻē aʻe e pili ana i nā pono.

5. ʻAno 105 mold (emi iho ma mua o 500 beers, ka poʻi mua a i ʻole ka hoʻāʻo ʻana)

Hiki ke hoʻohana ʻia ka hoʻoheheʻe alumini a i ʻole epoxy resin a i ʻole nā mea ʻē aʻe inā lōʻihi kona ikaika e hana i ka helu haʻahaʻa o nā hoʻokolohua.

Ka manawa hoʻouna: Jul-10-2023